Compare Aluminum Vs. Steel Mechanic Truck Bodies

08.19.22

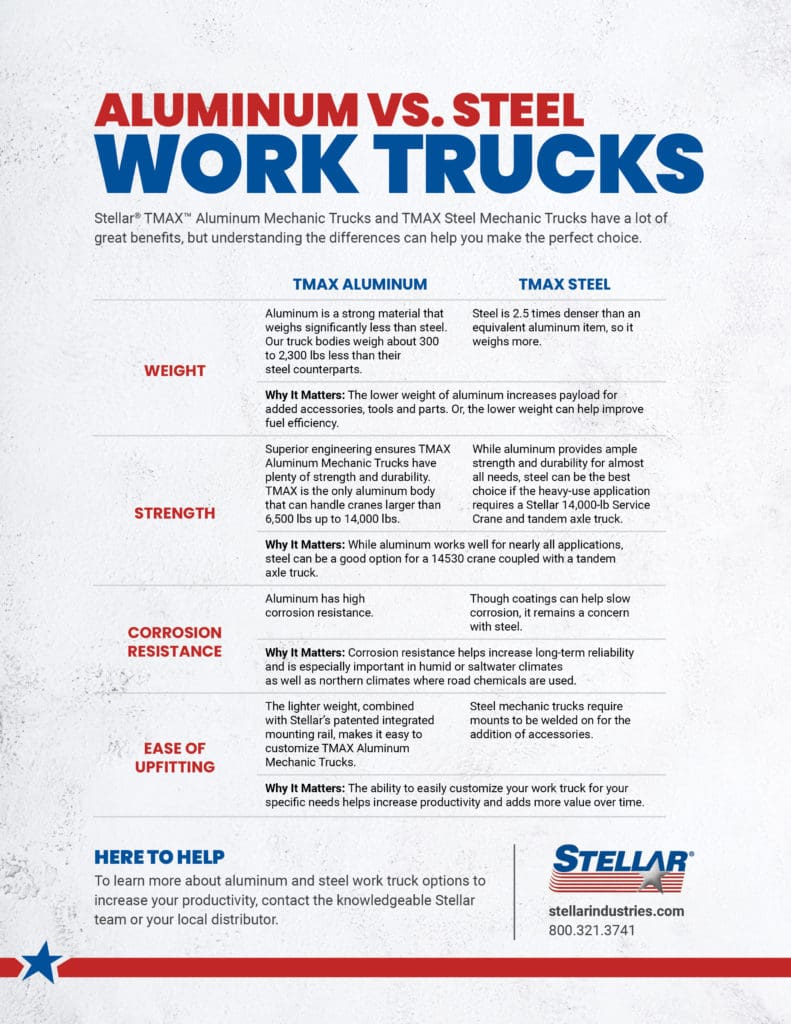

Mechanic and service trucks need to be rugged and durable, so the question comes up often: Is steel or aluminum better for trucks? You might see some top-level opinions, such as “steel corrodes and aluminum doesn’t” or “steel is stronger than aluminum” or “aluminum is lighter than steel.” To make a truly informed decision, you need to dig a lot deeper.

Stellar makes mechanic trucks and service trucks with aluminum bodies and with steel bodies, and a considerable amount of research, engineering and testing goes into each model. When making your choice between steel and aluminum truck bodies, there are many factors to consider that go beyond the basics.

For instance, if you would like to increase payload so you can add more service truck accessories, tools and parts, you might consider an aluminum body. Or if the work you’ll be doing is extremely heavy-duty and requires a Stellar® 14,000-lb Service Crane with a tandem axle truck, you might prefer steel. Read on for a more detailed look at aluminum vs. steel truck bodies.

The Case For Aluminum

Stellar was already a leading supplier of mechanic trucks before rolling out TMAX™ Aluminum Mechanic Trucks in 2017, and today aluminum is the more popular choice of customers. The two primary reasons for selecting an aluminum work truck are the lighter weight and corrosion resistance, and they are just the beginning:

- Lighter Weight. In the question of aluminum vs. steel truck bodies, aluminum allows for a lighter truck. The lower overall weight increases payload so that more truck equipment, tools and parts can be added. The lighter weight of an aluminum work truck also can contribute to better fuel efficiency, reduce the wear on truck components such as brakes and lower the chance of getting overweight tickets. TMAX Aluminum Mechanic Trucks are up to 2,300 pounds lighter than their steel counterparts, so aluminum might even allow you to run a smaller truck with lower operating costs and more maneuverability.

- Enhanced Corrosion Resistance. Corrosion weakens mechanic trucks and reduces performance. Areas with high humidity, heavy snows (with salted roads) or near saltwater are especially susceptible to corrosion. The aluminum construction of TMAX Aluminum Mechanic Trucks provides the corrosion resistance commercial trucks need for long-term service.

- Reduced CDL Needs. Also important when choosing a mechanic truck are the requirements of the driver. A commercial driver’s license (CDL) is required when a service truck has 26,000 pounds or higher. Because many field service technicians don’t have a CDL, the lighter weight of TMAX Aluminum Mechanic Trucks means that a service crane and other equipment can be added while still staying under CDL weight requirements.

Of course, the question of strength always comes up when comparing aluminum to steel, and that’s where superior engineering is essential. When designing TMAX Aluminum Mechanic Trucks, the Stellar team not only drew upon their own decades of experience in aluminum tire service trucks but also used engineering and design practices found in the automotive and aircraft industries to ensure outstanding structural integrity and strength.

All of our aluminum bodies have been designed and manufactured using steel where needed for additional strength (loadbed, crane box, torsion box, bumper) and aluminum where it makes sense for weight savings for more payload and to fight corrosion (sidepacks and doors). TMAX Aluminum Mechanic Bodies also feature an extruded aluminum mounting rail on top of the sidepacks for accessories like crane boom supports, air compressors, tool storage and more. This allows operators to move or add equipment on top of the sidepack without having to drill into the compartments, effectively keeping water out of the compartments.

The Case For Steel

While aluminum has a lot of benefits, Stellar continues to make steel TMAX Mechanic Trucks because sometimes steel is preferred or an application requires a Stellar 14,000-lb Service Crane with a tandem axle chassis.

One way to reduce weight on a steel work truck is to use lighter accessories, such as aluminum drawer sets or an aluminum lube skid.

Knowledgeable Team

For a quick comparison of aluminum vs. steel truck bodies, download our comparison sheet.

For detailed guidance, contact our team of experts or your local distributor. By understanding the needs of your application, your preferred accessories, the likely demands of the job and more, we can help you find the right aluminum or steel work truck to increase your productivity for years to come.