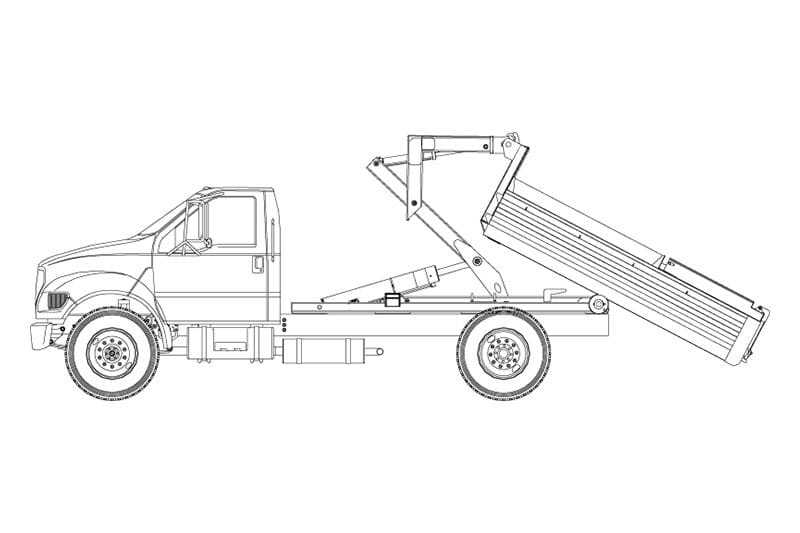

Shuttle24 Hooklift

Stellar designed this special hooklift from the ground up for the municipality or contractor who needs a short, maneuverable, single-axle truck with a high payload capacity. We determined through surveys of our distributors and operators that the most common body on this truck would be a dump body.

Designed for a truck with a CA of 84″, this model is proving its worth across the country in tough day-in, day-out use. The 96-10-24 has since proven it is as equally suited for a salt spreader, vacuum tanker, asphalt patcher or one of many other limited-use applications.

PrintAdditional Information

- Will accommodate bodies from 10′ to 12.5′ long and still retain the maximum rated dump angle on a 41″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls allow for precise metering of the manual hydraulic valve.

- 10-gallon, frame-mounted oil tank.

- Operating pressure is 4,200 psi.

- Hydraulic flow required is 16 gallons per minute.

- Patented dump/load interface.

- Hydraulic locks to prevent cylinder collapse in case of hose failure.

- Hook latch to prevent body from becoming detached prematurely.

- Mechanical rear-body tiedown latches.

- Resettable dump/tilt tabs.

- Hydraulic plunger valve to prevent front tilt movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Key Features

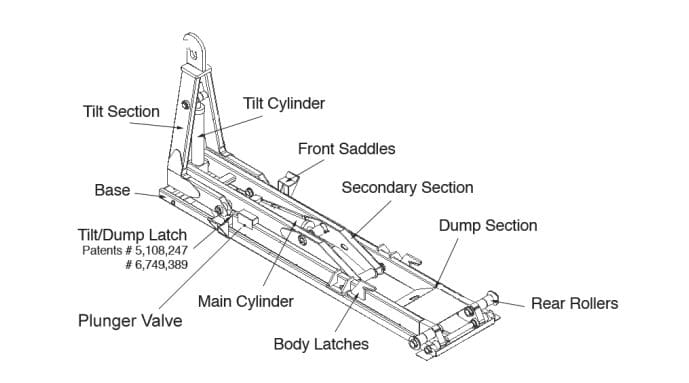

The diagram below shows a typical Stellar Shuttle Hooklift. Below is a detailed explanation of these components, which are an integral part of every Stellar Hydraulic Hooklift.

Base Section: The base section may also be called a subframe. All Stellar Hooklift hoists are tied together in one common framework. This base section not only adds strength to the hoist but also places less stress concentration on the truck chassis by providing additional structural support. The base section also provides for simple installation on most truck chassis.

Body Latch: The body latch is also referred to as the rear tiedown. Standard on Stellar Hooklift hoists are rearward-facing hooks that interface with a horizontal steel pocket or tab. As the body is pulled forward into the final storage position prior to transporting, the tabs will pull tight in the hook pockets. Hydraulic-activated rear tiedowns are optional on larger Stellar Hooklift hoists.

Dump Section: This component of the Stellar Hooklift pivots at the rear of the hoist and when the tilt engages the patented dump latch tabs, allowing for the container dumping function. The rear-body latches are attached to this component on all models, allowing the body to remain in the latches while in transit and dumping.

Front Saddles: Front saddles provide a place for the body to rest while the truck is in motion.

Lift Cylinder: The lift cylinder lifts the body onto the truck and provides the dumping movement. Our lift cylinders feature dual pilot-operated counterbalance valves, which provide optimum meter-ability and protection against sudden movement in the case of hose failure.

Tilt and Dump Latch: This unique patented feature is the basis of the Stellar Hooklift system. With a simple mechanical engagement between the tilt section and the dump section, the pivot point is changed from the secondary section (loading/offloading) to the rear of the truck (dumping). Resettable tabs protect the system from out-of-sequence operation.

Rear Rollers: With the unique Stellar Hooklift design, bodies are loaded and unloaded with a lift and roll movement. While unloading a body, the tilt section will lift the front of the body and roll it back. The tilt cylinder will continue rolling the body until the rear of the body contacts the ground.

Plunger Valve: The plunger valve will lock out all hydraulic fluid to the tilt cylinder when in the dumping mode. This prevents accidental release of the body while dumping.

Secondary Section: The secondary section acts as the main pivoting member for loading/offloading bodies. This component ties the tilt and dump sections together into one cohesive unit.

Tilt Cylinder: The tilt cylinder operates the tilt section of the hooklift and features a pilot-operated counterbalance valve on both extend and retract sides. The tilt section is a key component of the Stellar Hooklift. With Stellar’s unique twin-post design, line-of-sight visibility of the hook is available from the truck cab.

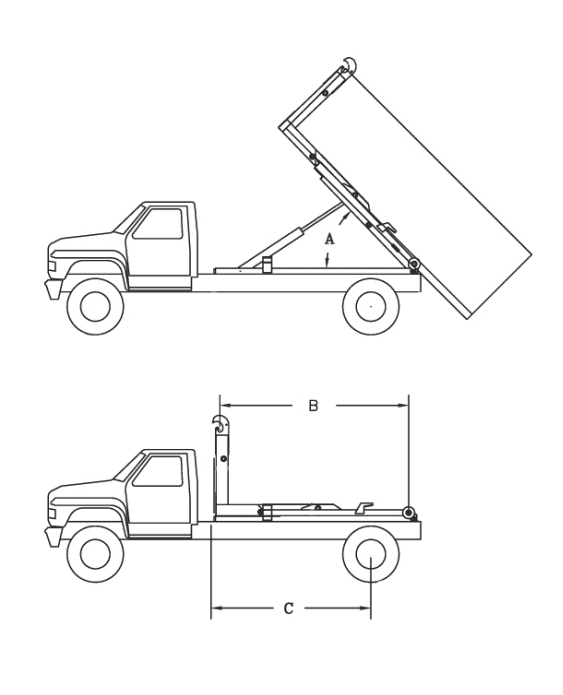

Specifications

| Description | 96-10-24 |

|---|---|

| Dump Angle (A): | 54˚ |

| Effective Length (B): | 115" (2,921 mm) |

| Cab to Axle (C): | 84" – 102" (2,134 – 2,591 mm) |

| Lift/Dump Capacity: | 24,000 lbs (10,886 kg) |

| Shipping Weight: | 2,500 lbs (1,134 kg) |

| Rec. Body Lengths: | 10' – 12.5' (3,048 – 3,810 mm) |

| Hook Height: | 54" (1,372 mm) |

| Min. Truck GVWR: | 26,000 lbs (11,793 kg) |

Related Articles

Unlocking Versatility: The Power of Hooklifts in the Waste Industry

Waste management and recycling pros are choosing the hooklift for its adaptability, revolutionizing waste handling beyond traditional methods. Explore the benefits of hooklifts for streamlined operations.

Revolutionizing Recycling: Stellar Exhibits NXT52 Hooklift at ISRI 2024 in Las Vegas

Stellar is thrilled to showcase its NXT52 Hooklift at booth #843 during ISRI 2024, the premier global event for the recycled materials industry, held from April 15 to 18, at the Mandalay Bay Resort & Casino in Las Vegas.

Stellar Welcomes Two Seasoned Professionals to Propel Demountable Sales

Ricky Lee Schoenfelder and Robert Pena join the team as Regional Sales Managers for Hooklift, Roll-Off and Container Trucks. Schoenfelder will serve the North Central Region and Pena the South Central Territory.

Ready to Get the Job Done?

Reach out to us today. With Stellar, you don’t just get tough, reliable products and equipment. You get real solutions to real problems — designed with you in mind.