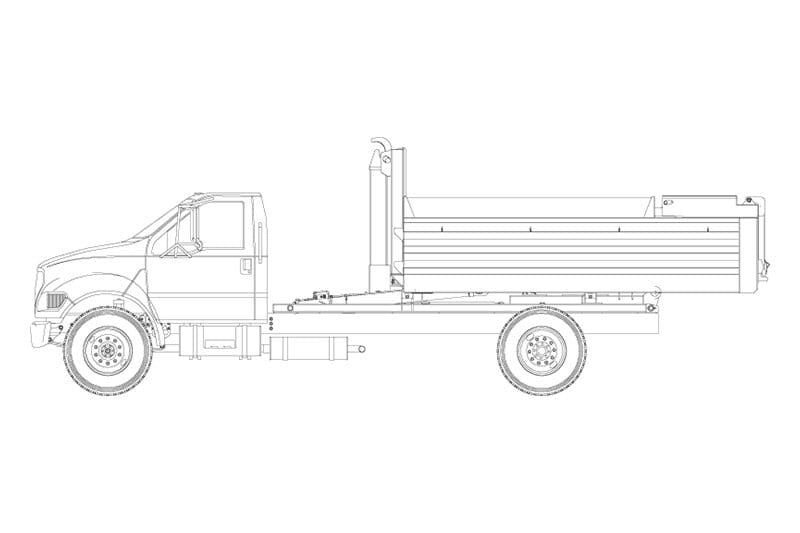

Slider20-S Hooklift

20,000-lb Capacity Sliding Jib Hooklift

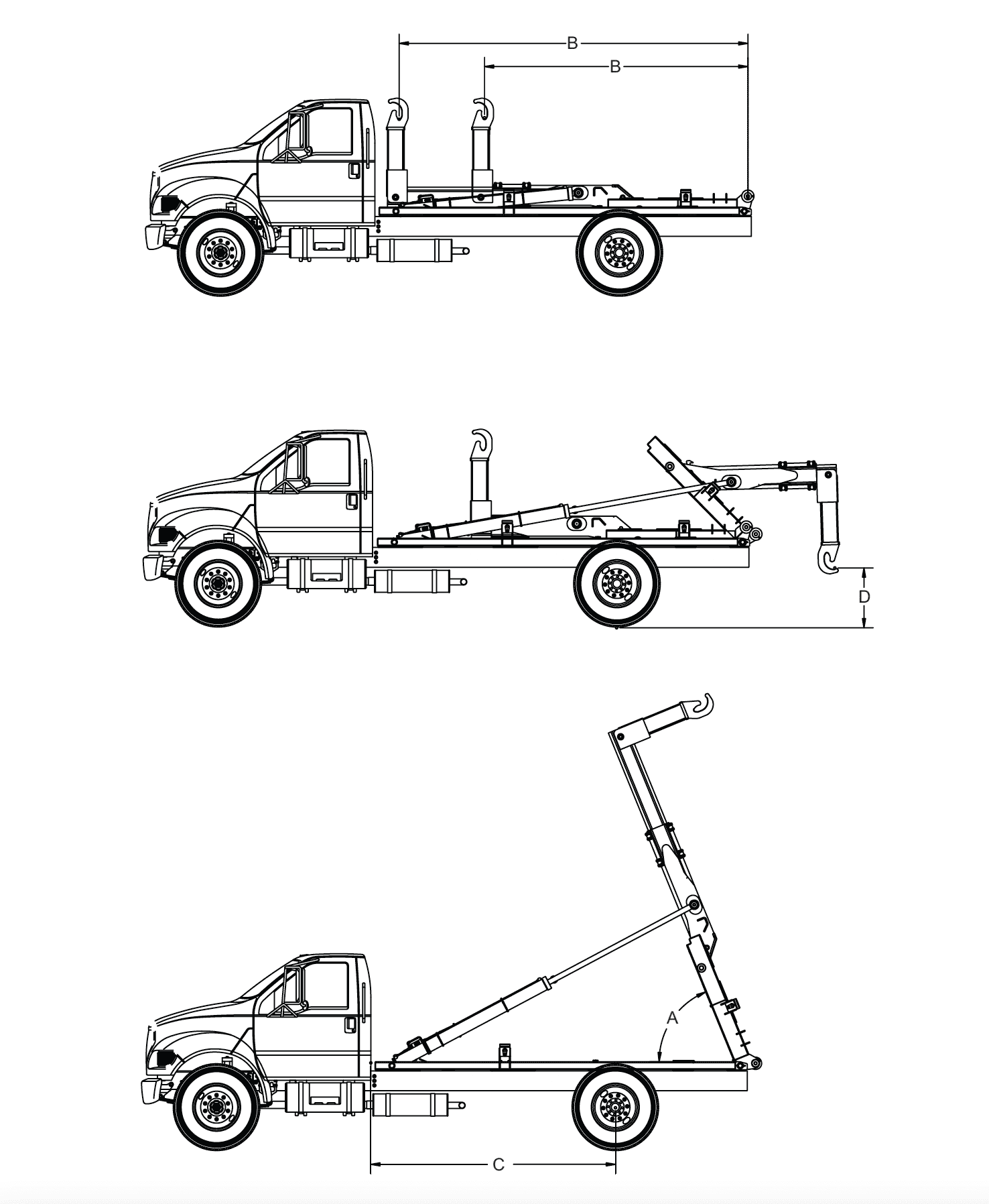

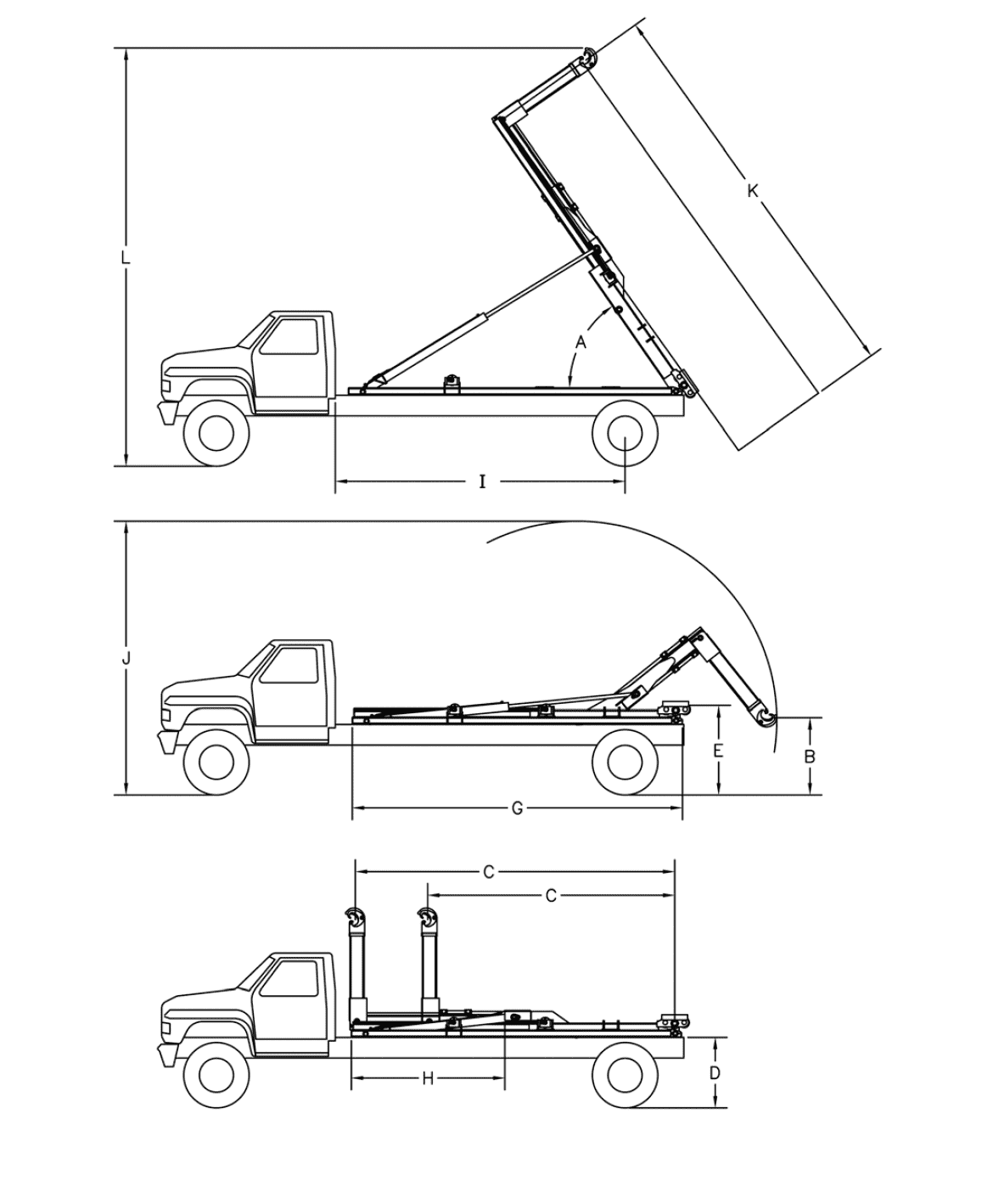

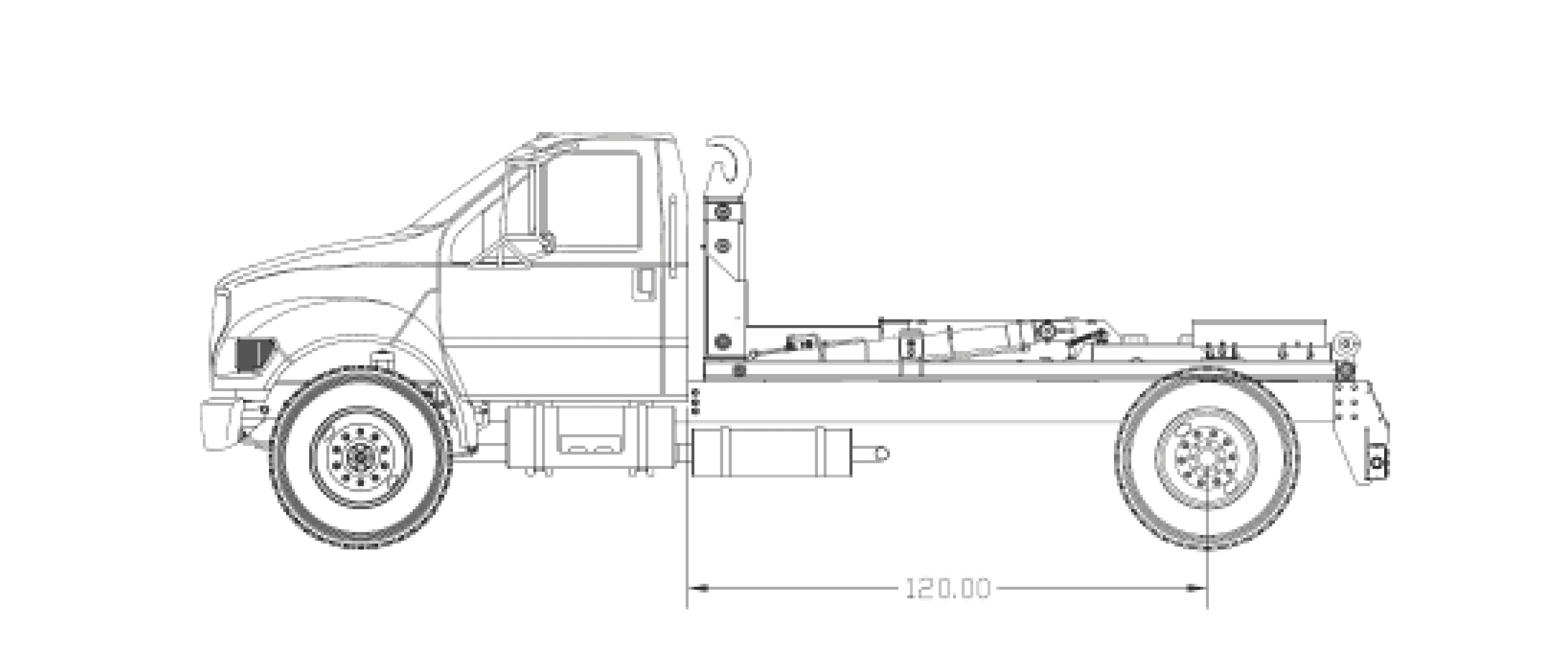

Discover how the Stellar® Slider20-S Hooklift can make your day-to-day operations more efficient. The Slider20-S is a body handling system mounted on a truck chassis that is capable of loading, unloading and dumping various bodies with lengths ranging from 10′ (3.0 m) to 14′ (4.2 m) with the use of a sliding rectangular jib. The rectangular jib reduces flex and provides greater structural integrity. The Slider20-S can accommodate capacities up to 20,000 lbs (9,071 kg). The maximum dump angle is 60° with all hook heights.

The Slider20-S is equipped with a telescopic jib and is available with 35.63″ (905 mm) or 54″ (1,372 mm) hook heights that are adjustable either manually or hydraulically to allow for working with various length and hook height containers.

PrintAdditional Information

- Will accommodate bodies from 10′ up to 14′ long and still retain the maximum rated dump angle on a 40″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Will accommodate various hook heights on containers with adjustable hook heights jibs, either with manual adjustable hook heights or hydraulic hook heights.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls allow for metering of the manual hydraulic valve.

- 25-gallon, frame-mounted oil tank.

- Operating pressure is 4,500 psi.

- Hydraulic flow required is 24 gallons per minute.

- Valve bank equipped with power beyond port.

- Mechanical dump/load interface.

- Hydraulic counterbalance valves to prevent cylinder collapse in case of hose failure.

- Inside or outside bolt-on, slide-through, rear-body tiedown latches.

- Plunger valve to prevent front jib movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Grease zerks at all pinpoints to allow purging of contaminants.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

Key Features

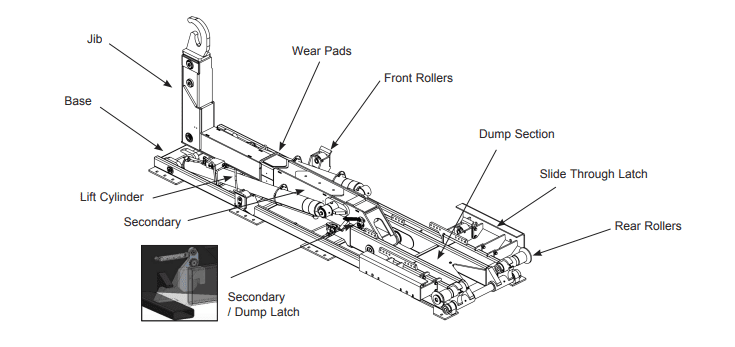

- Base section: The base section of a Stellar Slider may also be called a subframe. All Stellar Slider Hooklifts are tied together in one common framework. This base section adds strength to the loader and places less stress concentration on the truck chassis by providing additional structural support. The base section provides for simple installation on most truck chassis.

- Latches: Inside and/or outside bolt-on latches for ease of installation and replacement.

- Jib/Secondary: The sliding jib allows for a wider range of container lengths and a means to control the truck’s weight distribution while remaining in the latches. The jib and secondary booms are rectangular shaped for structural integrity. The jib is equipped with an adjustable hook height, either hydraulic actuated or manually adjustable, to allow for picking of various size containers.

- Wear pads: Easily replaceable wear pads for the jib/secondary boom assemblies can be changed in minutes and ensure long life for the jib/secondary assemblies. It’s not necessary to disassemble the hooklift to replace wear pads.

- Dump section: Dumping is accomplished through the rear pivot point. Jib and dump sections must lock together to support the full length of container/body when in the dump mode.

- Skid rollers: These three sets of rollers allow skid to roll freely forward and backward while operating the jib. They prevent long sills from wearing prematurely by not dragging steel on steel, and they eliminate the need to replace wear pads on base frame.

- Bushings and zerks: Bushings and grease zerks at all pivot points.

- Counterbalance valves: Counterbalance valves are used on all cylinders, protecting both extend and retract functions in case of a hydraulic hose failure.

- Pins: Carbon-steel and zinc-plated or type 17-4 stainless steel to prevent corrosion.

The diagram below shows a typical Stellar Slider Hooklift. Following is a detailed explanation of these components, which are an integral part of every Stellar Hydraulic Hooklift.

SPECIFICATIONS

| Item Description | Slider20-S – 35.63" or 54" |

|---|---|

| Dump/Lift Capacity: | 20,000 lbs (9,071 kg) |

| Dump Angle (A): | 60˚ |

| Effective Length (B): | 112" – 142" (2.85 – 3.6 m) |

| Cab to Axle (CA): | 108" – 120" (2.74 – 3.05 m) |

| Lowest Hook Height (D): | 35.63" HH: 28.5" (0.72 m) 54" HH: 8.63" (0.22 m) |

| Shipping Weight: | Manual Adj: 2,810 lbs (1,274 kg) Hydraulic Adj: 3,700 lbs (1,678 kg) |

| Rec. Body Lengths: | 10' – 14' (3.05 – 4.26 m) |

| Hook Height: | 35.63" or 54" (9.05 or 1.37 m) |

| Min. Truck GVWR: | 22,000 lbs (9,979 kg) |

Related Articles

Customer Video: Fleck & Son Stays Productive With Stellar® Hooklifts

View the video to see how Fleck & Son raises productivity with Stellar® Hooklifts and Service Trucks.

Customer Video: The Wall Company Ensures Uptime With Stellar® Equipment

Watch the video to see how Stellar® Mechanic Trucks and Container Carriers help The Wall Company maximize uptime.

Stellar Welcomes Southeast Regional Sales Manager for Demountables

Stellar welcomes Blair Cogburn as Regional Sales Manager in the Southeast, bringing 19 years of commercial work truck experience to the team.

Ready to Get the Job Done?

Reach out to us today. With Stellar, you don’t just get tough, reliable products and equipment. You get real solutions to real problems — designed with you in mind.