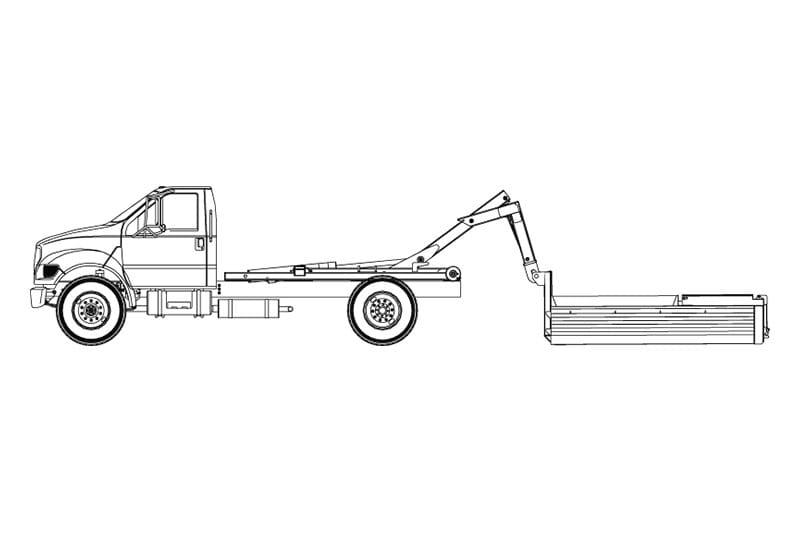

Shuttle16 Hooklift (Flex)

No other hooklift manufacturer currently offers the flexibility of the Stellar® Shuttle16. The Shuttle16 can handle dump containers ranging from 8′ to 15′ and flatbeds ranging from 10′ to 16′ and has a lifting capacity of up to 16,000 lbs. It has a maximum dump angle of 50˚ to 54˚, depending on the length of body.

The Shuttle16 maintains all of Stellar’s efficient operational and mechanical features such as the in-cab controls and body locks to ensure stability and secure attachment. All Stellar Hooklifts feature permanently lubricated greaseable bushings, zinc-plated pins and an efficient low-flow, high-pressure hydraulic system.

Customer Story: See how Junk Rescue depends on the reliability of Stellar Hooklifts.

37 available in Inventory

PrintAdditional Information

- Will accommodate bodies from 8′ up to 15′ long and still retain the maximum rated dump angle on a 41″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities.

- Transmission-mounted PTO and hydraulic pump required to power the hooklift.

- Standard in-cab manual controls that allow for metering of the manual hydraulic valve.

10-gallon-capacity, frame-mounted oil reservoir. - Maximum hydraulic flow is 16 gallons per minute.

- Patented dump/load interface.

- Counterbalance valves to prevent cylinder movement in case of pressure loss.

- Mechanical rear-body tiedown latches.

- Resettable dump/tilt tabs.

- Hydraulic plunger valve to prevent front tilt movement when the dump frame is raised.

- Permanently lubricated and greaseable bushings used throughout.

- Grease zerks at all pinpoints to allow purging of contaminants.

- Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

- All weldments painted with two-part polyurethane enamel.

- Full length dump frame with front saddles to support the body during the dump mode.

- Greaseable rear load rollers.

Key Features

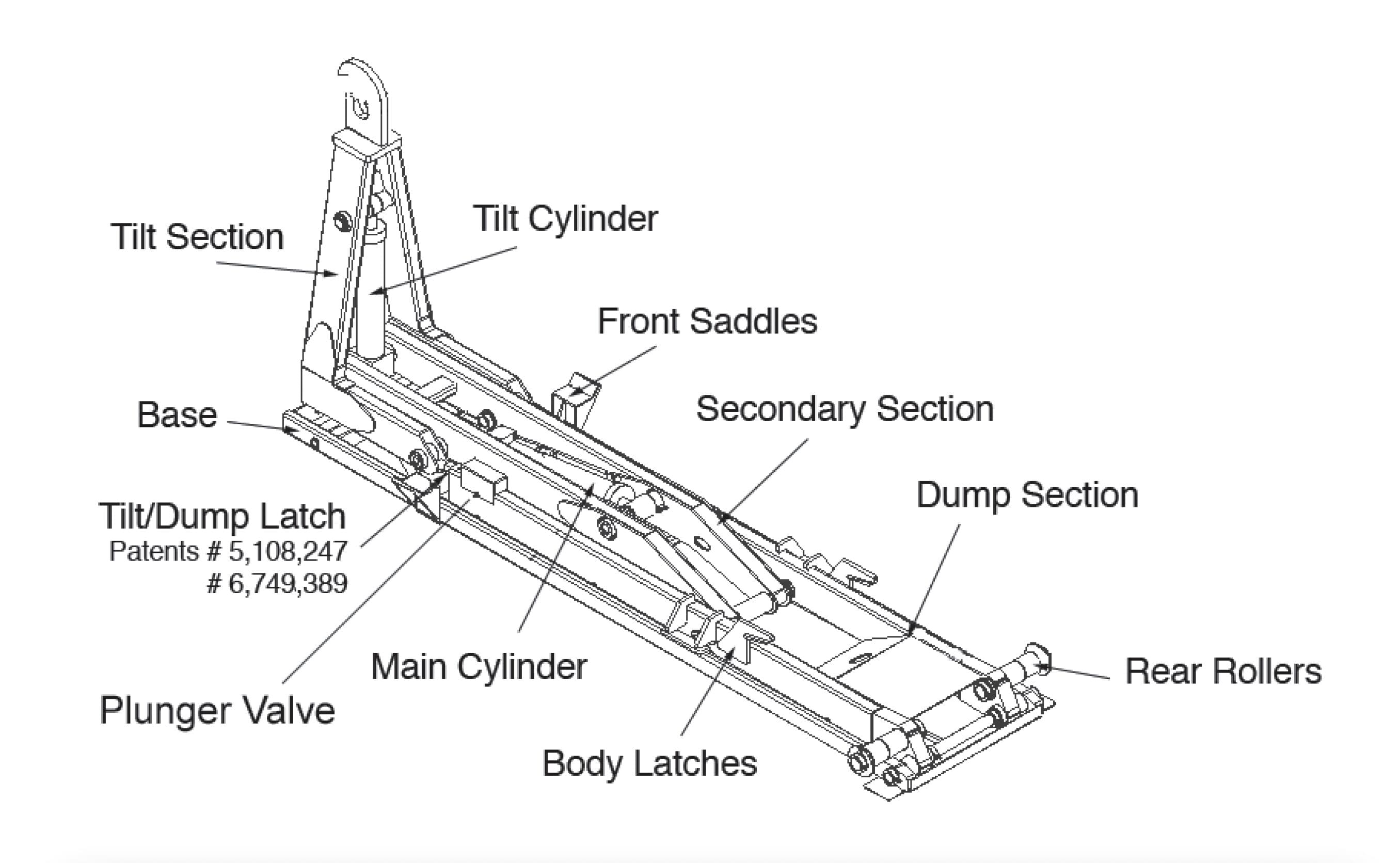

The diagram below shows a typical Stellar Shuttle Hooklift. Below is a detailed explanation of these components, which are an integral part of every Stellar Hydraulic Hooklift.

Base Section: The base section may also be called a subframe. All Stellar Hooklift hoists are tied together in one common framework. This base section not only adds strength to the hoist but also places less stress concentration on the truck chassis by providing additional structural support. The base section also provides for simple installation on most truck chassis.

Body Latch: The body latch is also referred to as the rear tiedown. Standard on Stellar Hooklift hoists are the rearward-facing hooks that interface with a horizontal steel pocket or tab. As the body is pulled forward into the final storage position prior to transporting, the tabs will pull tight in the hook pockets. Hydraulic-activated rear tiedowns are optional on larger Stellar Hooklift hoists.

Dump Section: This component of the Stellar Hooklift pivots at the rear of the hoist and when the tilt engages the patented dump latch tabs, allowing for the container dumping function. The rear-body latches are attached to this component on all models, allowing the body to remain in the latches while in transit and dumping.

Front Saddles: Front saddles provide a place for the body to rest while the truck is in motion.

Lift Cylinder: The lift cylinder lifts the body onto the truck and provides the dumping movement. All Stellar Hooklift lift cylinders feature dual pilot-operated counterbalance valves which provide optimum meter-ability and protection against sudden movement in the case of hose failure.

Tilt and Dump Latch: This unique patented feature is the basis of the Stellar Hooklift system. With a simple mechanical engagement between the tilt section and the dump section, the pivot point is changed from the secondary section (loading/offloading) to the rear of the truck (dumping). Resettable tabs protect the system from out-of-sequence operation.

Rear Rollers: With the unique Stellar Hooklift design, bodies are loaded and unloaded with a lift and roll movement. While unloading a body, the tilt section will lift the front of the body and roll it back. The tilt cylinder will continue rolling the body until the rear of the body contacts the ground.

Plunger Valve: The plunger valve will lock out all hydraulic fluid to the tilt cylinder when in the dumping mode to prevent the accidental release of the body while dumping.

Secondary Section: The secondary section acts as the main pivoting member for loading/offloading bodies. This component ties the tilt and dump sections together into one cohesive unit.

Tilt Cylinder: The tilt cylinder operates the tilt section of the Stellar Hooklift and features a pilot-operated counterbalance valve on both extend and retract sides. With Stellar’s unique twin post design, line-of-sight visibility of the hook is available from the truck cab.

Cable Hoist Container Hooklift Adapter Kit

Save money by converting your cable hoist containers for use with your Shuttle16 (Flex). Learn more.

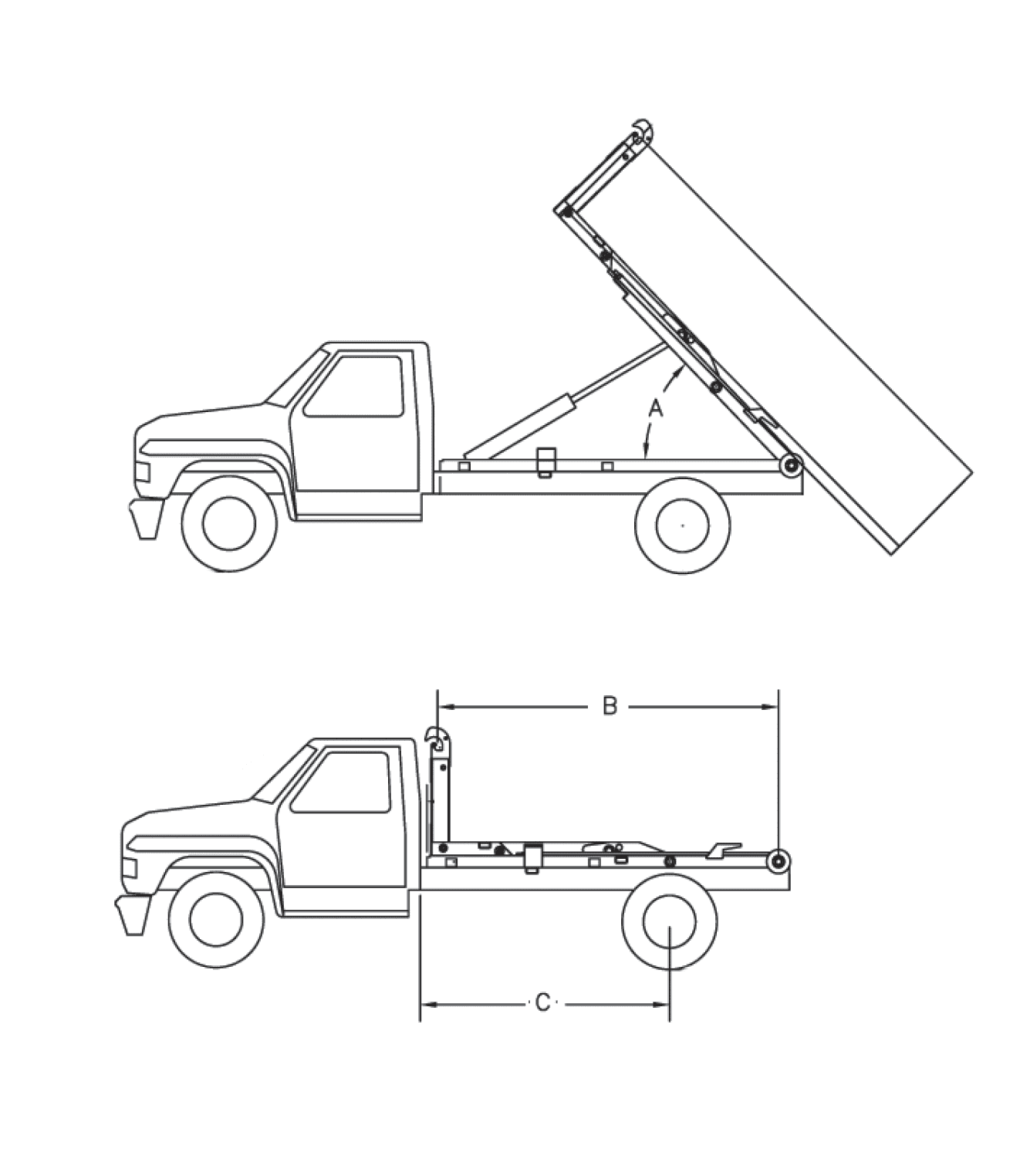

SPECIFICATIONS

| Item Description | 60-8 | 84-10 | 108-12 | 120-14 |

|---|---|---|---|---|

| Dump Angle (A): | 54˚ | 53˚ | 54˚ | 50˚ |

| Effective Length (B): | 91" (2,311 mm) |

115" (2,921 mm) |

142" (3,607 mm) |

151" (3,835 mm) |

| Cab to Axle (C): | 60" (1,524 mm) |

84" – 96" (2,134 – 2,438 mm) |

108" – 120" (2,743 – 3,048 mm) |

120" – 130" (3,048 – 3,302 mm) |

| Lifting/Dumping Cap: | Up to 9,000 lbs (4,082 kg) |

Up to 16,000 lbs (7,257 kg) |

Up to 16,000 lbs (7,257 kg) |

Up to 16,000 lbs (7,257 kg) |

| Shipping Weight: | 1,275 lbs (578 kg) |

1,360 lbs (617 kg) |

1,615 lbs (733 kg) |

1,650 lbs (748 kg) |

| Rec. Body Lengths: | 8' – 9' (2,438 – 2,743 mm) |

10' – 12' (3,048 – 3,658 mm) |

12' – 14' (3,658 – 4,267 mm) |

13' – 15' (3,962 – 4,572 mm) |

| Hook Heights: | 35.63" (905 mm) |

35.63" (905 mm) |

35.63" (905 mm) |

35.63" (905 mm) |

| Min. Truck GVWR: | 10,500 – 15,000 lbs (4,763 – 6,804 kg) |

10,500 – 26,000 lbs (4,763 – 11,793 kg) |

10,500 – 26,000 lbs (4,763 – 11,793 kg) |

10,500 – 26,000 lbs (4,763 – 11,793 kg) |

RESOURCES

Videos

Related Articles

Customer Video: Fleck & Son Stays Productive With Stellar® Hooklifts

View the video to see how Fleck & Son raises productivity with Stellar® Hooklifts and Service Trucks.

Customer Video: The Wall Company Ensures Uptime With Stellar® Equipment

Watch the video to see how Stellar® Mechanic Trucks and Container Carriers help The Wall Company maximize uptime.

Stellar Welcomes Southeast Regional Sales Manager for Demountables

Stellar welcomes Blair Cogburn as Regional Sales Manager in the Southeast, bringing 19 years of commercial work truck experience to the team.

Ready to Get the Job Done?

Reach out to us today. With Stellar, you don’t just get tough, reliable products and equipment. You get real solutions to real problems — designed with you in mind.