What You Need to Know about Service Truck Tool Box Drawers

12.16.22

Service trucks and vans must be stocked with all the tools and parts needed to service and repair equipment. That means it’s crucial for these vehicles to have sensible storage configurations.

A high-quality, well-organized toolbox system can make the most of your available space and enhance the productivity of any mechanic truck, service truck or service van operator across a spectrum of industries — construction, agriculture, mining, oil and gas and more.

When you find the right combination of drawer sizes and configuration options, you can improve efficiency and boost your earning potential by being able to service more customers on a daily and weekly basis.

Here’s what you need to know about current trends and developments in work truck storage systems:

The Shift toward Aluminum Continues

The trend toward greater adoption of aluminum storage vs. steel toolboxes continues as service technicians are trying to find any way they can to lighten up their work trucks and increase payload while having a solid, durable platform to carry tools and components. Aluminum’s lightweight durability and corrosion resistance have earned the confidence of the industry not only in mechanic truck bodies, but also in service truck toolbox systems that hold up to the rigors of everyday hard work.

Stellar has taken all the well-known features of our heavy-duty steel line of work truck toolboxes and put them into aluminum systems for virtually indestructible yet lightweight systems that meet any demand.

Stellar’s American Eagle brand of heavy-duty aluminum toolbox systems offers the same 500-lb individual drawer capacity as their heavy-duty steel counterparts but weigh 30 percent less so you can carry more tools and parts on your work truck. Stellar’s American Eagle lightweight aluminum toolbox systems have a 250-lb capacity per drawer and are 50 percent lighter than heavy-duty steel.

Your aluminum vs. steel decision may boil down to price vs. weight savings. Depending on the toolbox system, you can expect to invest a couple hundred dollars more for aluminum compared to steel. But if you’re putting multiple drawer sets in a mechanic truck, service truck or service van, the pounds of payload savings can really add up.

Service Vans Are Growing in Popularity

One upfitting trend we are seeing is increased interest in upfitting lightweight service vans like Transit Vans and Sprinter Vans. As a result, Stellar now offers products for service van upfits to provide an easier, more affordable way for crews to service light-duty equipment.

Stellar offers a range of quality options to get your work van your way. A heavy-duty workbench and toolbox combo optimizes storage and features a steel cabinet and aluminum T-handle drawers. The butcherblock work surface is durable enough for you to perform work on the bench without damaging the drawer set. At 56″ wide and 20″ deep, you’ll have ample room to complete simple tasks from your van.

You can add an air compressor and configurable lube skid, too. Additions like these allow you to work from the comfort and convenience of your van. And with tools, parts and equipment close by, productivity will be maximized.

Look for Key Differences in Strength and Durability

Rugged reliability is essential for toolbox systems, which must endure the abuse of everyday work and harsh conditions. Stellar offers hardworking toolboxes for the most demanding environments with custom-made options that are the most durable products on the U.S. market today and built to the highest standards to optimize your productivity.

Not every toolbox manufacturer offers 500-lb drawer capacity. Stellar offers it in both steel and aluminum drawer slides to hold up to the demands of rigorous use and support heavy tools and equipment. Our 500-lb capacity is certified by SGS, a leading inspection, verification and certification company.

Unlike some other brands that use plastic drawer latches, Stellar offers metal latches for the ultimate in durability and security. In fact, Stellar performed testing in an R&D lab where individuals beat on the back of the drawers on our units and our competitors’ units. On the competitive units, the doors would pop open or latches would break. Stellar’s drawer sets wouldn’t budge or break thanks to the strong and sturdy metal latches.

Stellar is so confident in the strength and quality of our service truck tool storage units that we offer a full lifetime warranty on the slides, latches and handles.

Plentiful Options Help You Get the Setup You Need

There is a wide variety of options and accessories available, so you can configure the perfect drawer system to meet your work needs and style. Stellar drawer system sizes and configurations are custom-made to your specifications. Each system is engineered to fit your truck’s or van’s compartment and configured with the drawer sizes that will work best for you.

Here’s a closer look at Stellar’s configurations:

- Choice of heavy-duty steel or aluminum with 500-lb-capacity per drawer.

- All drawer widths feature a pull handle or our unique key-locking T-handle, which provides for one-handed operation and conceals the latch mechanism for heavy-duty protection.

- Side panels have a standard 2.5″ riser built into them with mounting slots pre-punched for multiple riser heights.

- The top shelf is included with all drawer units and is designed to telescope out 5.5″ on each side of the drawer set. In most installations, this will provide a full shelf in the body compartment and give solid reinforcement.

- Individual drawer slides are easily removed from the set, providing convenience if you need to move items closer to the job or retrieve a lost tool.

- Various combinations of 3″-, 5″- and 7″-high service truck tool box drawers are available.

- System widths are available in 1″ intervals.

First-Class Customization Options

Want even more ways to customize? Stellar offers additional accessories and options:

- Drawer lightbar: Maximizing productivity starts with visibility. Drawer lightbars with bright, long-lasting LED lights help to optimize work truck lighting in dark environments and provide light into open service truck tool box drawers where compartment lights cannot.

- Egg-crate dividers: Create multiple compartments in each drawer; great for storing fasteners, fittings, miscellaneous parts and odd-shaped tools.

- Non-slip drawer liner: Provides protection for valuable tools and helps keep them in place for organization.

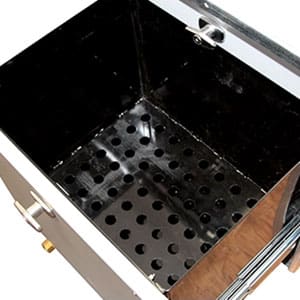

- Oil filter/drain drawer: Provides a central location for disposing of oil filters, which helps keep the truck clean and more organized. The oil filter drain unit includes a heavy-duty drawer with a perforated floor for filter drainage. A standard drain valve can be located in the front or back for eventual draining.

- Custom colors: Choose from white, gray, blue, yellow, red, black and green to customize the look of your truck at no extra cost.

- Bolt Bins: An excellent storage system for nuts, bolts, fittings and more, with aluminum dividers that allow you to custom configure each bin.

- Hinged drawer lid: Useful for the storage of paperwork, a laptop or other valuables. It also provides a sturdy work surface for assembling or sorting.

Selection Always Starts with Purpose

Sometimes customers want guidance when choosing new toolbox systems; in other instances, mechanics familiar with their setup know what they want.

Regardless of your situation, when thinking about drawer sets, the question, “What is the purpose for the truck?” will lead you to what you need storage for. Knowing what will be stored helps determine the height of the drawers; 3″, 5″ and 7” drawer heights are typical but can be configured nearly any way you need them. How many drawers of each height, how many drawer sets for the build and how much weight they need to be able to handle all are determined by what you’re storing based off what the truck is used for.

Typically, on a mechanic or service truck, heavy-duty drawer sets are used with each drawer being able to handle 500 pounds of weight each. Thinking back to your main objective for your truck can help determine if the weight savings from an aluminum drawer set is needed or if steel will suffice. You can determine which handle style you prefer like a classic T-handle or pull handle and select from the various options to get the ideal drawer set for efficiency and, in turn, profitability.

Learn More About Stellar’s Service Truck Tool Box Drawers

If you’re looking into service truck tool box drawers and toolbox systems or ready to try Stellar products, contact Stellar today, find a distributor or check out our units in stock. We are here to support you every step of the way.